Importance Of Slab Formwork

Regardless of the type of floor slab, the Slab Formwork system is mandatory and necessary to support such a large weight;

- The Slab Formwork must be strong, durable, and resistant to wear and atmospheric media.

- Slab Formwork is generally lightweight and easy to operate, and can be used quickly and easily.

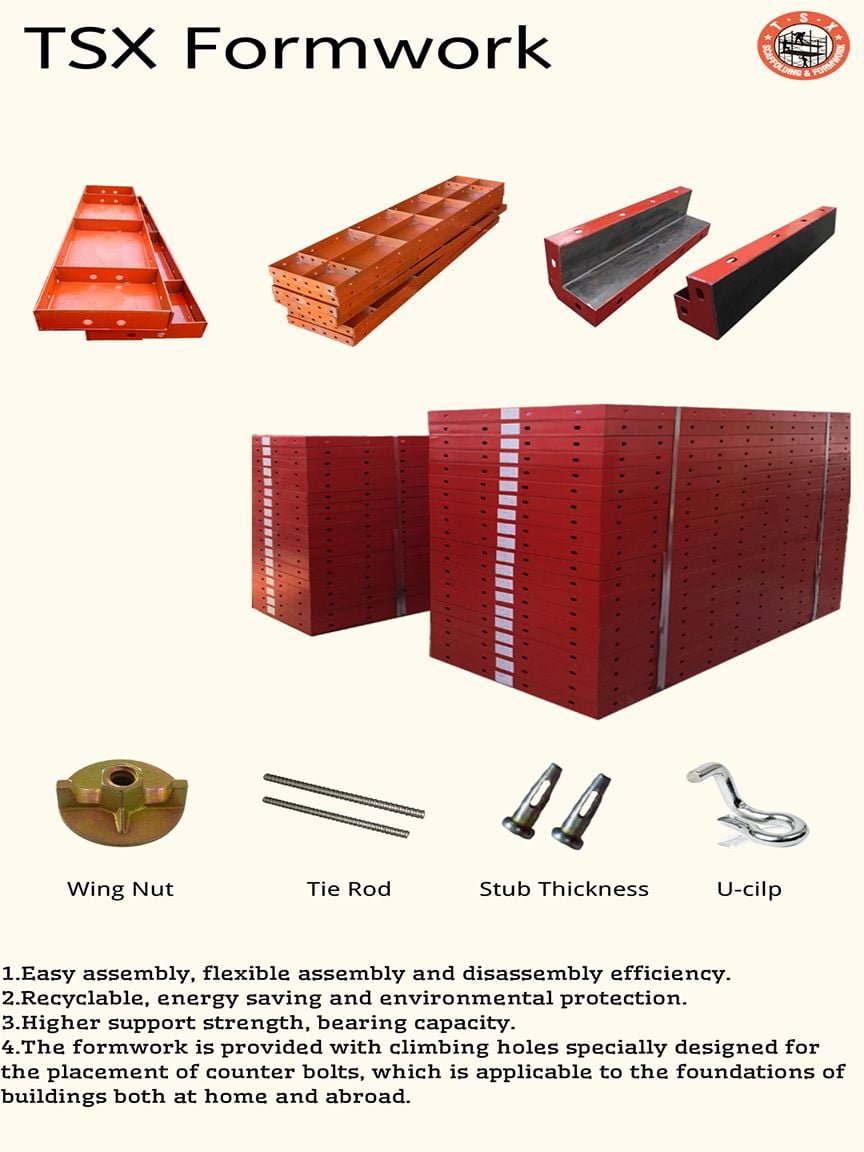

- Slab Formwork Details

- Packing Of Slab Formwork

Slab Formwork is a common two-dimensional structural element of modern buildings, consisting of a flat horizontal surface made of poured concrete. It supports the floor by distributing the load on the beams of the building structure. To this end, a horizontal Slab Formwork was designed and installed to support reinforced concrete before it hardens (mechanical properties).

Before the reinforced concrete walls, columns and slabs can really bear the live load, the Slab Formwork (panel) plays the role of “supporting” material during the solidification and hardening process.

FAQ

1. How is Slab Formwork calculated?

For simple square and rectangular forms, just multiply the length x width to know how many Slab Formwork you need. For a circular base, multiply the square of the radius by π (πr²). For irregular shapes, break them down into simpler squares and rectangles, then add up the total surface area.

2. What is Slab Formwork?

A Slab Formwork is a temporary form used to provide support for fresh concrete when placed in a structural member until the concrete sets. This helps the structural member gain sufficient strength to withstand its own loads and loads from other members.

3. Why is it important that Slab Formwork be strong?

As the concrete cools and hardens, it needs to be placed on the Slab Formwork all the way. The Slab Formwork basically supports all the weight of the concrete and the weight from other accessories. If it collapses, it will have a major impact on the project.

4. How is Slab Formwork calculated in Details?

For simple square and rectangular Slab Formworks in Details, simply multiply length x width to know how much formwork you need. For a circular base, multiply the square of the radius by pi (πr²). For irregular shapes, break these down into simpler squares and rectangles and add up the total surface area.

5.What is Slab Formwork in Details?

Slab Formwork in Details is a temporary construction used to hold the concrete in place while it sets. As concrete is very heavy, formwork must be solidly constructed and firmly braced and supported. To ease the removal of the formwork after the concrete is dry the Sheating must be well oiled before pouring the concrete.

6. How do you make Slab Formwork in Details?

Design and Calculation of Formwork Requirement of Slabs

Sheating – 25mm thick wooden planks.

Joists – 2″ x 3″ wood (50mm x 75mm) spaced at 400mm c/c.

Stringers – 2″ x 4″ wood (50mm x 100mm) spaced at 600 mm c/c.

Shores – Bamboo wood spaced at 600 mm c/c.

7. In the case of Slab formwork Details, what materials are usually made of?

The Slab formwork Details are made of wood or steel, and the surface in contact with the concrete is selected to provide the desired finish.

The Slab formwork Details and its associated fake work must have sufficient strength to support the weight of the wet concrete without significant deformation.

8. Under what circumstances can the Slab formwork Details be removed?

Generally speaking, once the Slab formwork Details gains sufficient strength, the Slab formwork Details is removed, although in some cases it may stay in place.

9. How to remove the Slab formwork Details correctly?

The removal of the Slab formwork Details should start with the removal of the vertical members first.

The crowbar should not be fixed on the side to remove the Formwork Materials, as it will damage the edges of the concrete.

Loose Slab formwork Details or any other materials found at the edges and corners will be removed.

The safety engineer should check the construction site before removing the Slab formwork Details to ensure proper conditions.

For the safety of workers, check whether the Slab formwork Details position provides sufficient support and a working platform to remove the template at a higher height.

10. What are the advantages of Slab Formwork Details?

Slab Formwork Details are manufactured using superior quality raw material that provides optimum quality and durability. To meet the technically advanced requirements of our clients, we design and construct Slab Formwork Details using the latest technology and techniques. Slab Formwork Details reduces capital investment and provides optimum quality.

11. Where Slab Formwork Details can be used?

Slab Formwork Details is particularly designed for slab construction in housing projects. It is a ready to use formwork system, With 4 prop legs, shuttering, timber beam H20 or steel walers, the Slab Formwork Details are pre-assembled in the factory and transported directly to Jobsite for application.

12. What are the characteristics of Slab Formwork Details?

1. Formwork For Concrete Slabsafe, fast shifting appliances, save time and cost.

2. Formwork For Concrete Slab After edge tables are erected, steel wire cables are used to fasten them to the embedded anchor bolts on the ground.

3. Formwork For Concrete Slab make sure low stacking height when transported and stored.

13. What is a Slab Formwork Details?

The Slab Formwork Details essentially support the weight of the concrete during curing and when the Slab Formwork Details are placed on the permanent supports. In most cases, the Slab Formwork Details can be reused, and the method of removing the Slab Formwork Details after the concrete has set is called stripping. After the Slab Formwork Details have been stripped, it must be cleaned to ensure that the surface of the panel remains straight and free of concrete build-up.

14. What are the Slab Formwork Details types?

Various types of Slab Formwork Details are available depending on the Slab Formwork Details material and the type of structural element being constructed. For example, Slab Formwork Details are used to construct concrete slabs. Slab Formwork Details are required when constructing suspended concrete slabs that are not directly supported by the ground. Slab Formwork Details include formwork, stringers, joists, bracing, and other support materials that enable concrete to be poured and set on the ground.

15. Can the Slab Formwork Details be customized?

Slab Formwork Details are not only used to create horizontal and curved surfaces, but also diagonal and vertical concrete structures. Today, Slab Formwork Details are highly modular and customized, allowing architects to create an almost endless array of concrete shapes and designs. Due to a large number of Slab Formwork Details available, it is important to use the most appropriate and economical type of Slab Formwork Details based on the budget and specifications of the project.

16. How about the Slab Formwork Details size?

The size of the Slab Formwork Details are as below: The length of the Slab Formwork Details usually is 1m,1.2m,1,5m,2m,2.5m, and 3m; The width of the Slab Formwork Details is 100mm–900mm; The height is 50mm or 55mm.

17. How long time Slab Formwork Details can be used?

The material of Slab Formwork Details is mainly in steel, and the nature of this material also means that the Slab Formwork Details can be reused many times.

18. How about the weight of Slab Formwork Details?

The weight of Slab Formwork Details is influenced by the size and thickness of Slab Formwork Details. We will calculate the weight of Slab Formwork Details for you according to your demands.

Concrete Metal Form-Hot

Types of Hot-Selling Concrete Metal Form

Concrete Metal Form