Advantage Of System Formwork

- System Formwork is universally applicable

By using only one system to flexibly form walls, columns and slabs, the utilization of components is high - System Formwork can be quickly and easily assembled

Fast working procedures due to simple template rules

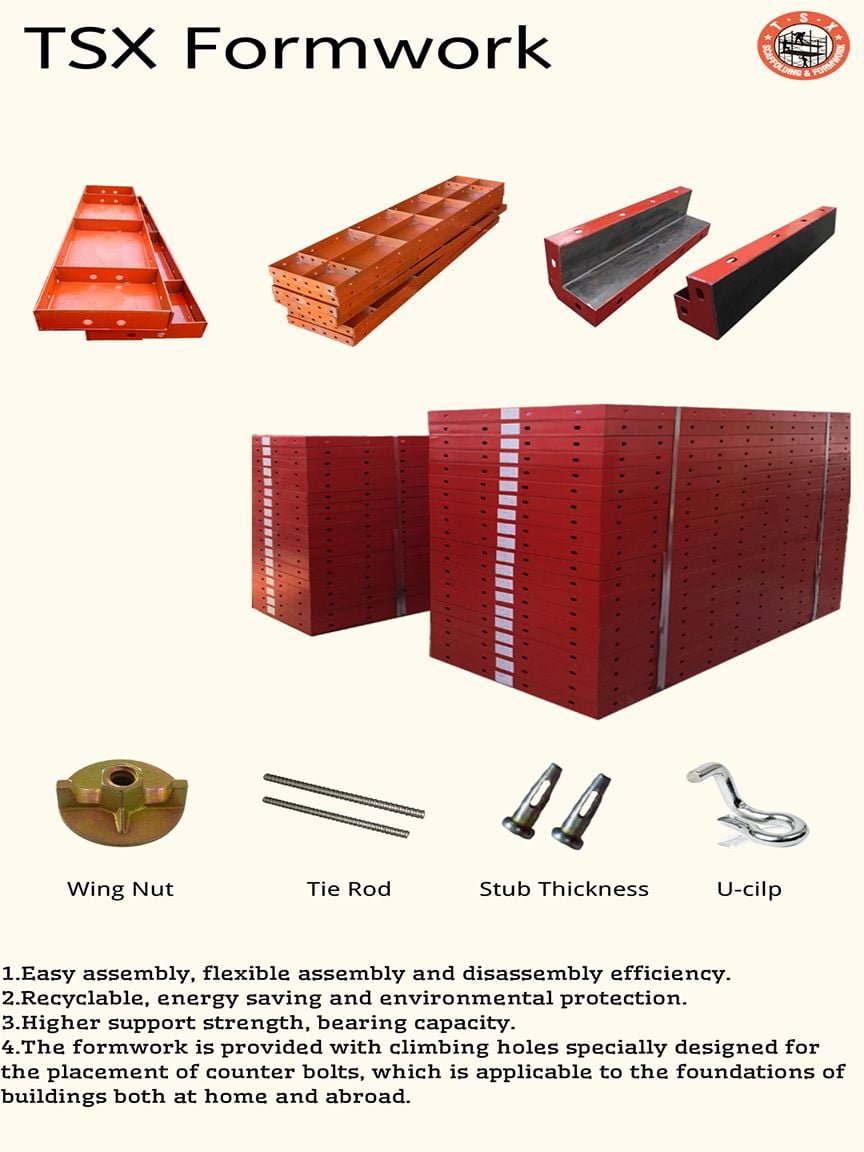

- Details Of System Formwork

- Packing Of System Formwork

Importance of System Formwork

It is easy to understand why steel is a better and more cost-effective choice for System Formwork. Steel is very durable, does not absorb moisture, and achieves a clean concrete finish, which is the perfect long-term solution. After all, as long as the System Formwork is properly maintained, the template can be reused. For these and more reasons, consider using steel to make System Formwork. It has a wide range of uses and can be used in almost any structural application involving concrete.

FAQ

1. What is the purpose of System Formwork?

System Formwork is a mold in which fresh concrete is poured and compacted. The purpose of the System Formwork is to support the reinforced concrete safely until it reaches sufficient strength. System Formwork can be temporary structures or permanent molding.

2. What conditions must the System Formwork meet?

①The System Formwork can bear the static load and live load.

②The System Formwork can maintain its shape and cannot be warped or deformed.

③The joints of the System Formwork must be leak-proof.

④System Formwork should use reusable materials.

3. What is the difference between Steel System Formwork and Aluminum System Formwork?

Steel System Formwork is becoming more and more popular due to its long service life and repeated use. Steel System Formwork can be used for multiple projects and being reusable is a viable option.

①The Steel System Formwork is sturdy and durable and has a long service life.

②Steel System Formwork waterproof.

③The Steel System Formwork can reduce the honeycomb effect in the concrete.

④The Steel System Formwork is easy to install and remove.

4. What is System Formwork?

System Formwork means the surface of the form and framing used to contain and shape wet concrete until it is self-supporting. System Formwork includes the forms on or within which the concrete is poured and the frames and bracing which provide stability.

5. What are the Advantages of System Formwork?

The advantages of System Formwork are durability and robustness. It provides a uniform and smooth surface finish to the structure. System Formwork is reusable and easy to fix and remove.

6. How to ensure System Formwork quality?

First of all, we have a test report about the System Formwork. Secondly, you can find a third-party testing agency to verify our System Formwork quality.

7. About OEM System Formwork:

We can customize for almost any System Formwork project.

We have professional engineers who can match and make System Formwork for you according to your drawings and your ideas.

8. What does the wall look like after using the System Formwork?

Using wood or other materials to make concrete system Formwork sometimes leaves a texture after the concrete surface is fully cured.

However, the use of System Formwork leaves a perfect and clean concrete finish.

9. Bearing capacity of System Formwork:

Steel is a very strong metal, and when used in System Formwork, it can withstand very heavy loads.

This makes System Formwork an ideal choice for large concrete projects and small projects.

10. What is System column Formwork?

System column formwork is a type of concrete formwork. Concrete formwork is a mold made of steel, aluminum, timber, plastic, or other materials in which wet concrete is poured to achieve a desired shape and size for construction.

11. What is vertical System Formwork?

Crane lifted panel systems are commonly used on building sites to form vertical elements and usually consist of a steel frame with plywood, steel, plastic or composite facing material. Panels are connected together flat on the ground to form larger individual crane-lifted units.

12. How many times can System Formwork be used?

The number of times the System Formwork is used depends on the material of the formwork, mainly plywood, steel and wood formwork, and steel formwork.

The number of plywood reuses is about 10-15 times.

The steel and wood formwork takes about 20-30 times because the panels are made of plywood but can be replaced.

Compared with the first two types of System Formwork, the steel formwork can be reused about 200-300 times, and can still be re-sold to recover costs after the completion of the project.

13. What features are required for a high-quality System Formwork?

1. Resistance to the pressure of new concrete, pouring in the process of concrete gushing speed and vibration tamping speed.

2. High-quality and smooth concrete finish.

3. The sturdy structure supports and effectively strengthens both horizontal and vertical to maintain shape and stability.

14. Why choose a steel System Formwork over a wood formwork system?

1. Compared with wood formwork, steel System Formwork has stronger durability and service life. In addition, they are reused more frequently.

2. Steel System Formwork is easy to install and disassemble.

3. Using steel System Formwork ensures the quality of the concrete surface and does not require further treatment.

4. Steel System Formwork does not absorb moisture from concrete.

5. Steel System Formwork does not shrink or deform.

Concrete Metal Form-Hot

Types of Hot-Selling Concrete Metal Form

Concrete Metal Form